After buying one of the sweet P60 dropins from Mattaus, I decided to build what I think is as close to my ideal EDC light as I can come up with. Most of my EDC items are in my briefcase, not in my pocket, so being super tiny isn’t a consideration – my EDC light just can’t be huge, and the L2D fits the bill rather well. I don’t have anything against tail switches, I just felt like this setup would be pretty cool if I could get it rigged up with a reliable switch.

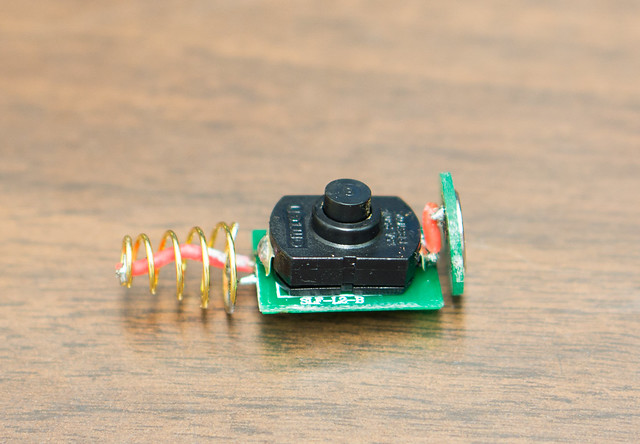

First off, I wasn’t crazy about the stock head, so I swapped it out for an L2T head with a flat stainless bezel. And swapped in a UCL from flashlightlens.com for the stock glass lens as well. I mocked this up once with the BLF17DD driver and it melted the stock switch’s innards in less than 10 minutes of use on high. So I tore it back down and replaced the stock switch with an Omten, replaced the stock spring on the battery side of the switch with the one in the pics (with a 22ga wire bypass), and rewired the contact on the dropin side of the switch. I also added a braided spring inside of the stock spring in the tailcap. The Omten switch doesn’t line up perfectly, but it works just fine with the little plastic plunger in the switch boot removed.

The dropin from Mattaus is a beast. Very heavy. The ground screw was a little tricky to wire up for me, but I got it done. Also added two blobs of solder on the spring side outer rim to help with grounding and to (hopefully) keep the spring side components from getting crushed when the head is tightened down.

The LEDs are dedomed XP-L V5 2A, dedomed in gas. Arctic Silver under the noctigon MCPCB, 20 or 22 ga wires on everything. Before changing the switch and modding the springs, it was pulling between 3 and 4 amps on high from a fresh Panasonic NCR18650PF… with the new switch and all the spring mods, it is now pulling a steady 6A on high from the same battery after about 20 seconds. The silver P60 dropin soaks up a whole bunch of heat. I ended up adding some foil tape to get it good and snug in the host, and heat transfer seems to be pretty good – once the dropin is saturated, it kicks the heat out to the outside of the head with a vengeance. So, I’m pretty pleased with the way it’s setup now – because of the dropin, the light can be run on high for several minutes before needing to worry about either the LEDs or my hands getting too hot.

Switch by itself

Completely disassembled

Driver & Foil

Switch alignment (sidebar, part of my L2D was glued together by solarforce - red stuff visible on threads. haters.)

Assembled Side Shot

Front Shot

I wish I had a way to measure lumens or kcd output… but I don’t. Here are a handful of beamshots from my back yard. Unfortunately, I don’t really have any ‘normal’ lights to benchmark any of this, as nearly all of my lights are modified in some way or another and many are generally in pieces on my workbench until I decide I’ve perfected the light. And that doesn’t happen real often. So, I used three lights in the beamshots to hopefully convey some idea of what this thing looks like in person. The photos seem slightly underexposed on my monitor – in person the spill is wider for all three of these lights. Hotspot looks fairly accurate though.

Control Shot

L2M with dedomed XM-L2 U2 1A driven at about 3.8A, smooth reflector

Convoy S3 with 3-XPL V5 2A dedomed with standard Qlite at 3.04A

L2D with 3-XPL V5 2A dedomed driven at about 6A

All shots taken with Sony NEX-7 at 10mm (15mm full-frame equivalent), F4, 2.5 seconds, ISO 400, auto white balance. These are the first beamshots I’ve ever taken, so any pointers on taking better ones would be appreciated.

All in all, I’m not too crazy about the DD driver. It is brighter than my S3 with the same LEDs at 3.04A, but I don’t know that the additional brightness is going to be worth giving up a bunch of runtime. I’ll probably keep it the way it is for a few months and see at that point if I’d rather have it at 3A. Kinda curious what it would look like with a non-PWM driver. All that said, so far in messing around with it, the brightness on level 3 is more than enough for most tasks outdoors, and I like that the DD driver has a lower-low than what a 7135 driver can provide.